Cutting More Ribs

I actually like cutting sheet metal. It isn't always easy and the pieces can be very hazardous to one's body (I wear tough gloves) if one isn't careful. I learned about sharp edges when I was young, cutting fallen tree limbs after a northeast hurricane back in the 80s. The tree saw went neatly into my thumb and now I am smarter. Funny how that works?

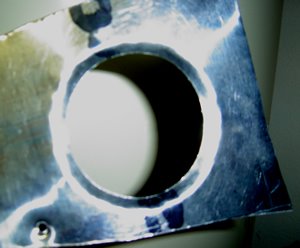

The pictures show the .020 aluminum sheet on the living room floor. The living room is about 30 degrees cooler than the garage, which is nearly 120 degrees. I keep a fan in there but 120 degrees blowing around may as well be 120 degrees not blowing around. I just make sure I keep some paper on the floor so that my bare feet don't find any aluminum slivers later!

I have all the rib blanks cut and now I just have to clean them up and give them the tabs. The tabs will then be the surface that the wing skins will be riveted to. More cutting! Woo hoo!

Labels: Wing